The sample case components of the first production run arrived mid-day yesterday.

I can't remember when was the last time I felt so excited and anxious!

Fitting the sapphire crystal, case back crystal, seals, mid case and bezel then inserting the movement and winding crown for the very first time was an experience I'll remember forever!

The good news: mechanically, all fits well, exactly as per drawing / design.

And equally importantly, the steel finish is just amazing. As much as I am trying not to be subjective, the watch feels at least as good as any $5K Swiss timepiece.

As we speak, I am wearing the zero/nine Pilots. Since the dial and hands are not ready yet, a provisional minute hand is fitted so the watch does tell the time.

For the next few weeks, until the dial is finished, I will have the opportunity to wear it and to check it for timekeeping, water resistance as well as to get a 'general feel' of the watch on my wrist.

Attached below are couple of images for Premium subscribers.

I know that some of you are eager to place your order. While the most challenging and most difficult part of the manufacturing is now successfully completed, I don't want to get distracted with sales before the dial and hands are in stock.

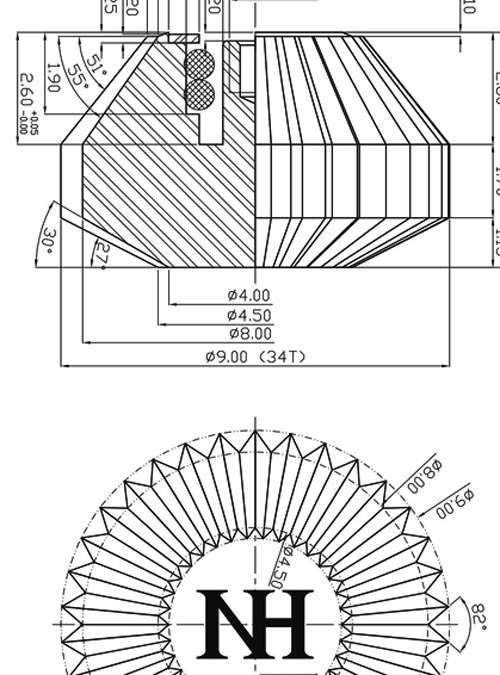

Final dimensions:

Case diameter: 44.2mm

Bezel : 44.0 mm

Thickness: 12.3mm

Winding crown: 9mm

Movement: manual wind.

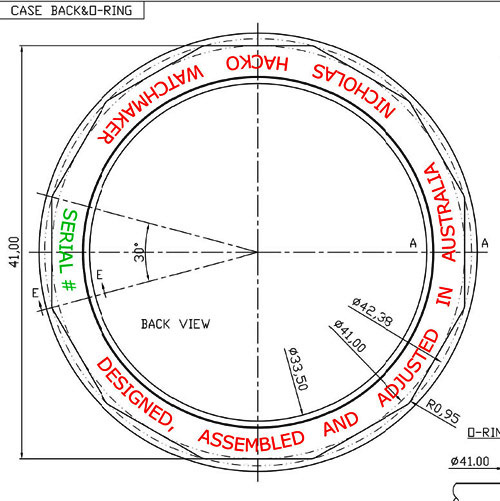

3 piece case with screw-lock bezel and screw-lock case back, sapphire crystal front glass 2.0mm.

Manual wind Unitas [Swiss] movement, the very same base calibre as used in Panerai manual wind watches. Additional finish: Cote de Geneva finish.

Water resistant to 10 bar min.